What: Simulated two-phase droplet generation and ferrofluid magnetic field behavior in

microfluidic systems using COMSOL and MATLAB.

Why:

To gain experience in microfluidic CFD simulations, understand mesh-dependency analyses, and learn how to

develop physics-based models to validate experimental data.

How:

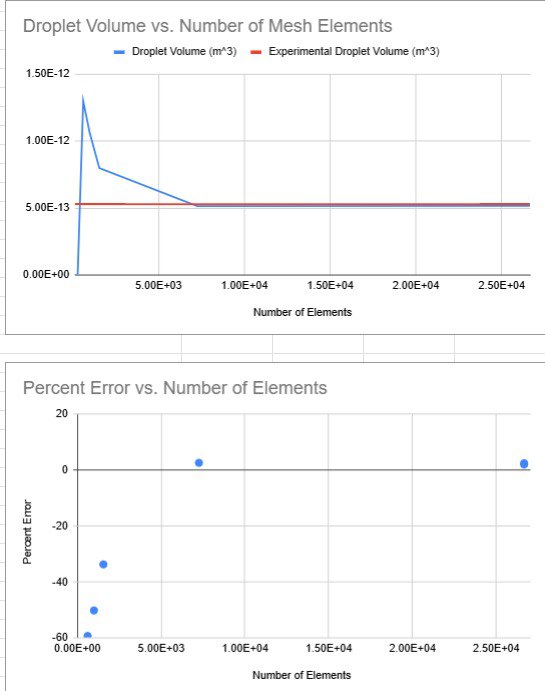

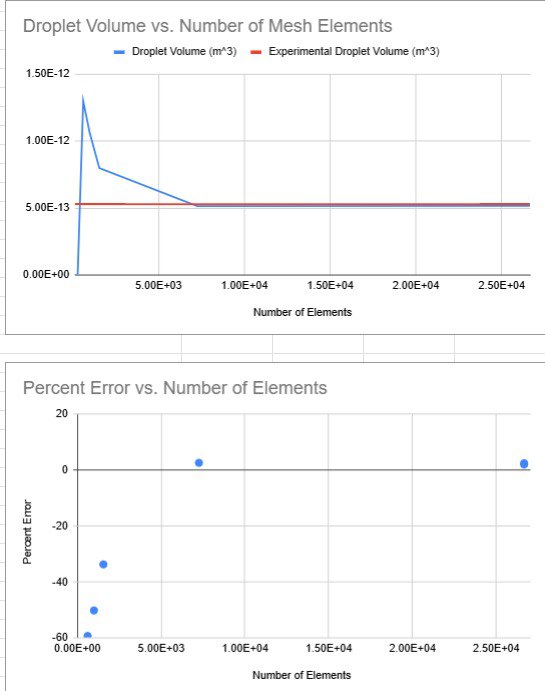

In COMSOL, I set up a two-phase level set simulation to model droplet formation in a cross-flow

droplet generator using silicone oil and a 10% glycerol–water mixture. I performed a mesh-dependency study by

varying mesh fineness across multiple iterations. For each case, I calculated droplet volume using a surface

integration at the outlet and compared results to experimental data to balance accuracy and computational

efficiency.

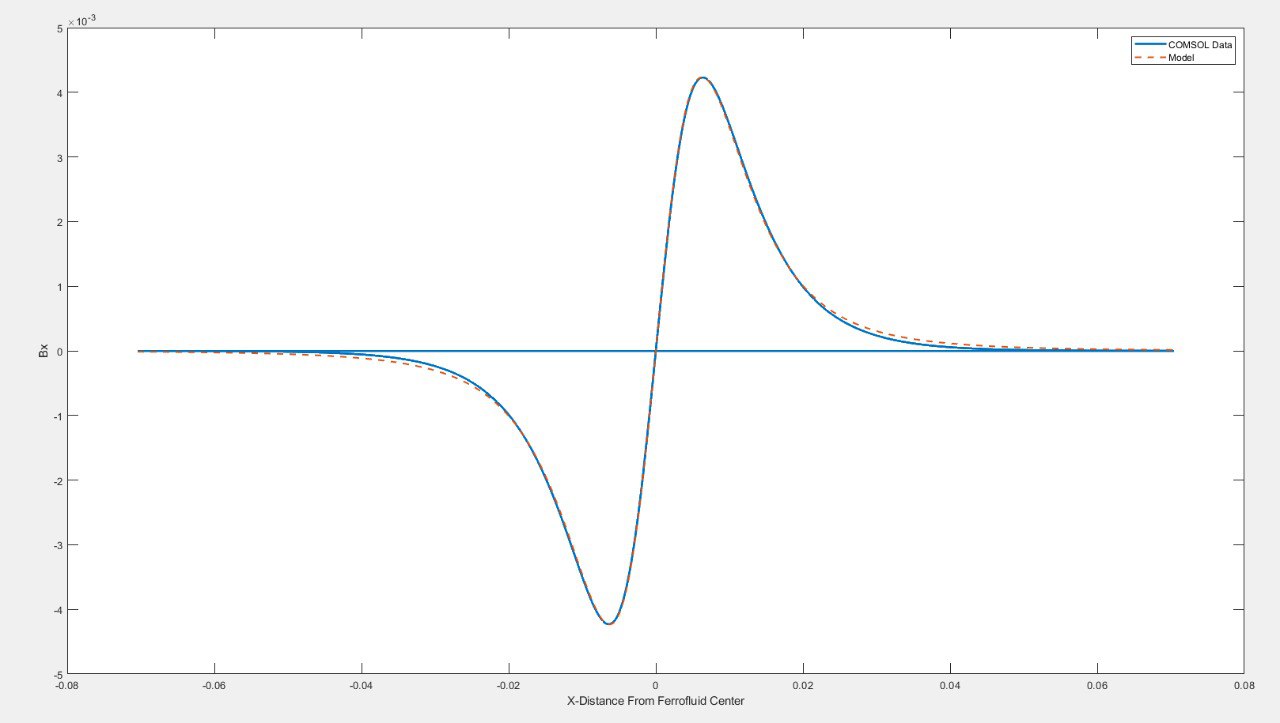

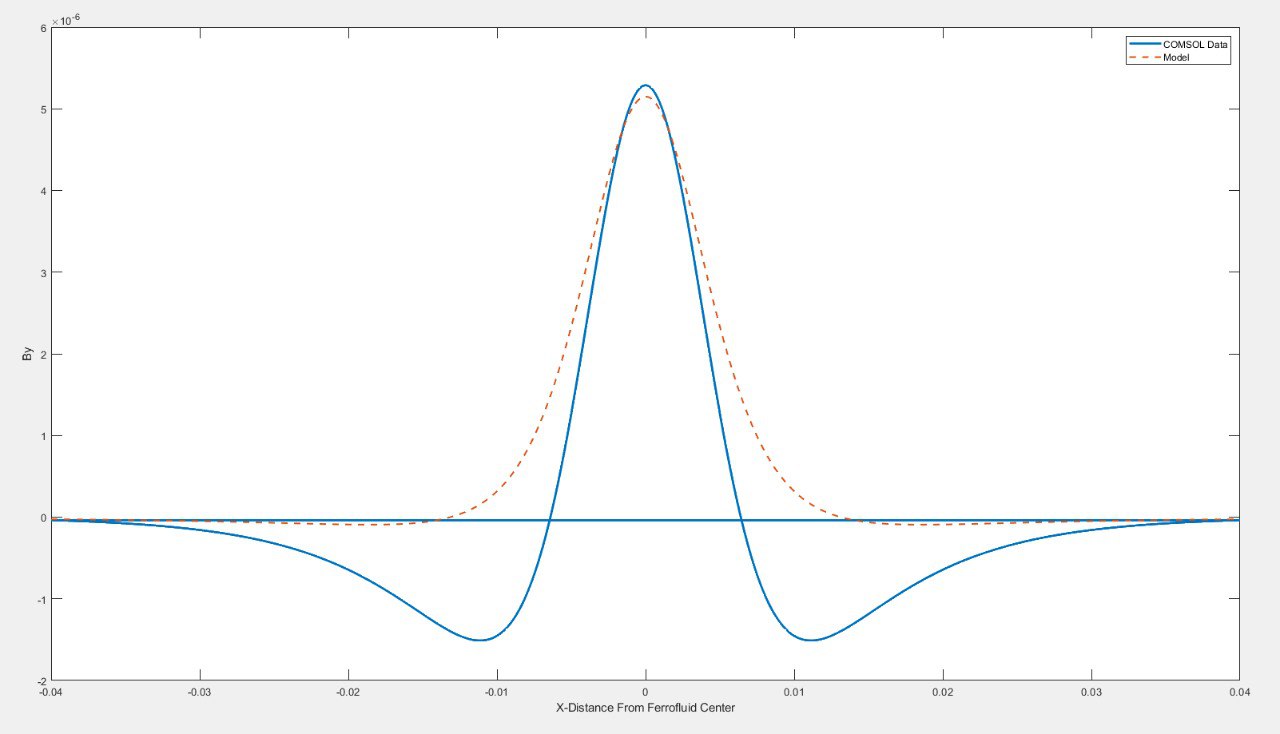

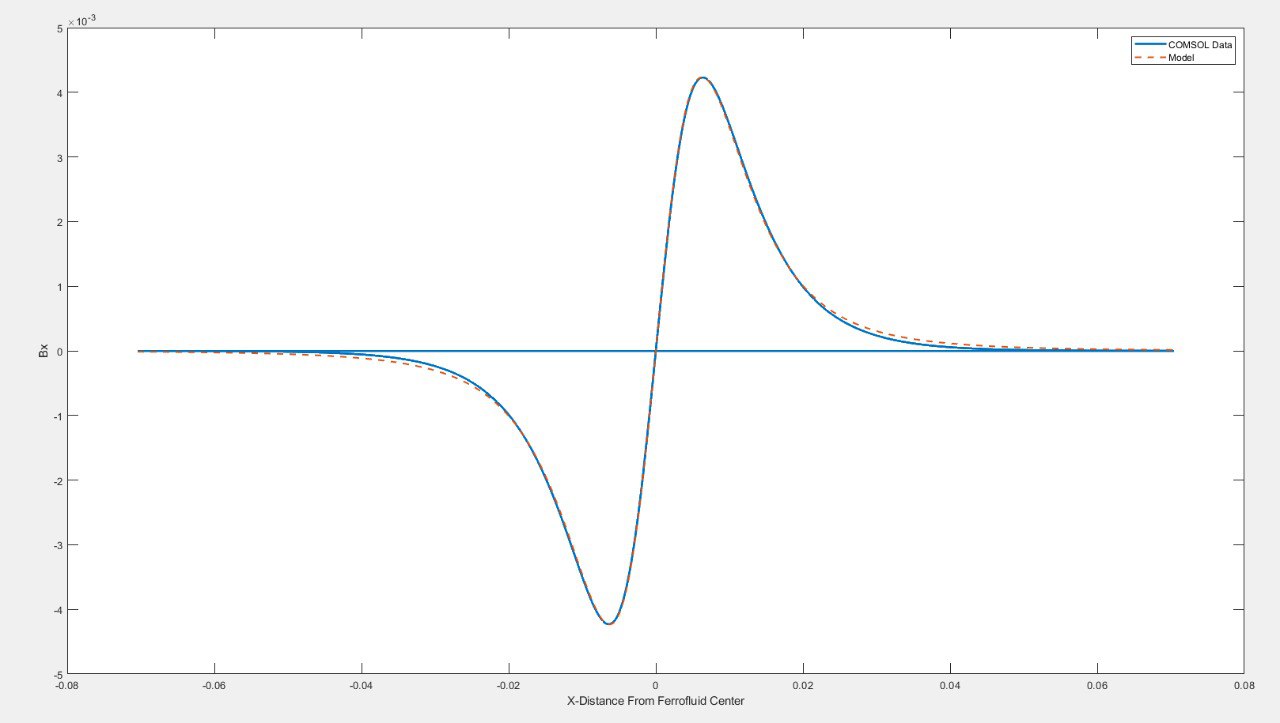

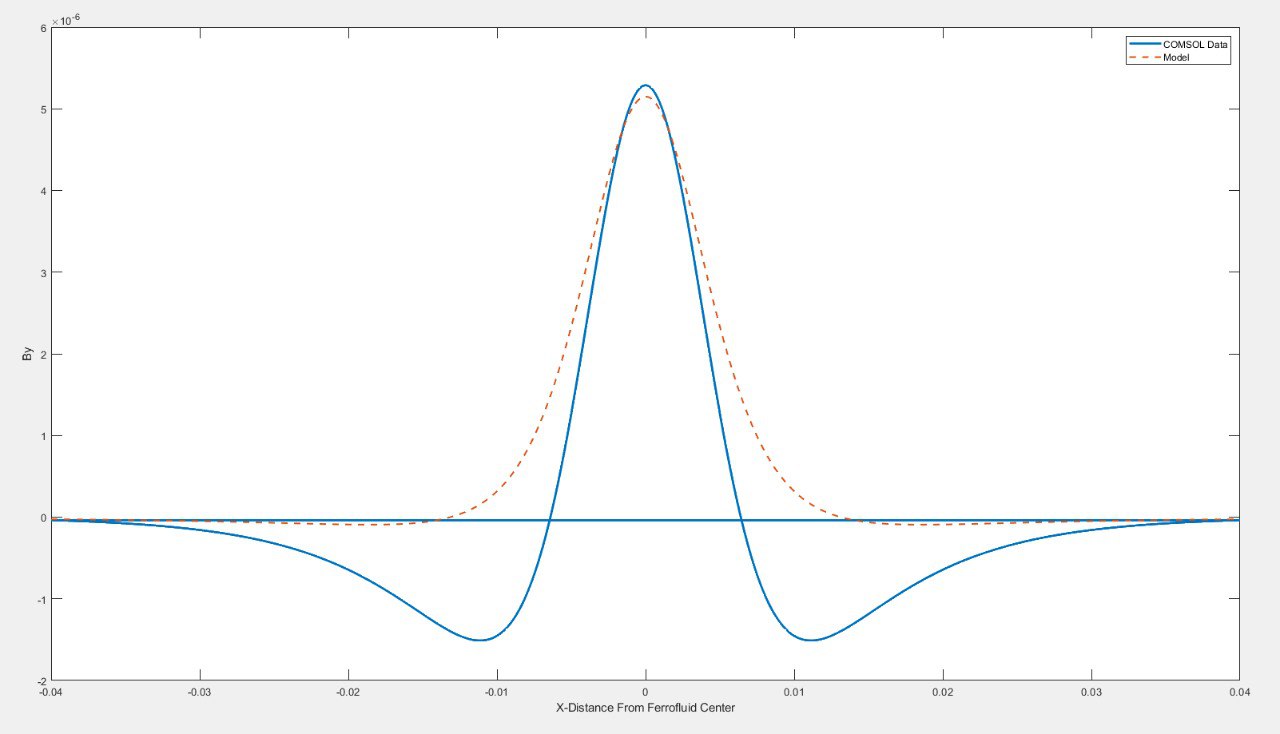

Separately, I used MATLAB to fit a physics-based model to magnetic field data across a ferrofluid in a

microfluidic chip, influenced by a permanent magnet. This model helped predict ferrofluid motion based on its

position relative to the magnet.

Results: In the end, I identified that the "finer" mesh option yielded optimal

accuracy with only

2.65% error in droplet volume. The magnetic field model successfully predicted ferrofluid behavior, enabling a

better understanding of magnetically driven flows in microfluidic chips.